Delivering design, engineering, manufacturing &

repair solutions with quality, service and savings.

PARTS DESIGN & MANUFACTURING SOLUTIONS

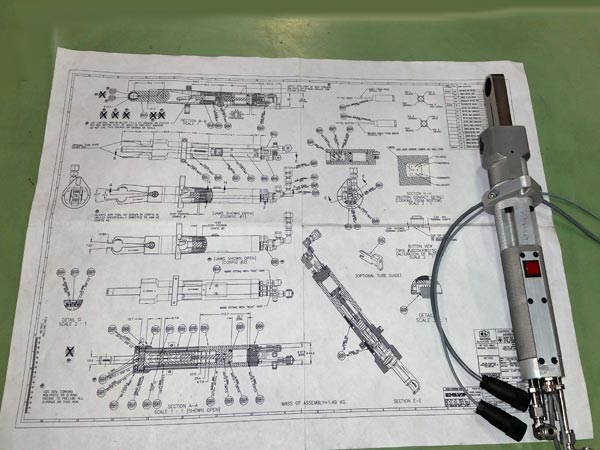

Design Services Unlimited offers complete design, engineering, manufacturing, tooling and repair solutions, including close tolerance grinding. Based in Detroit, MI – the automotive capital of the world – we deliver solutions to make your current product/processes work better.

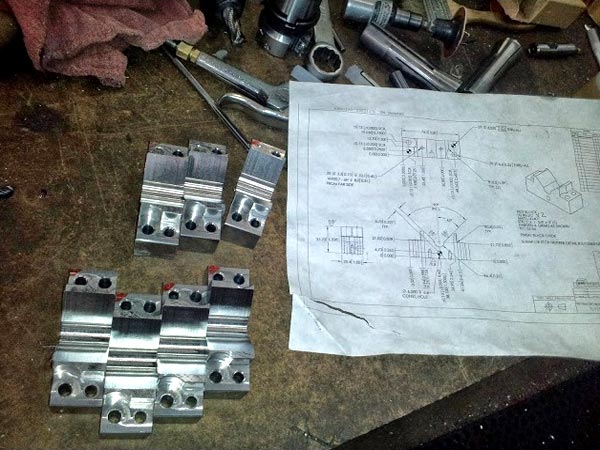

We are leaders in solving challenges that other vendors just can’t seem to get right: from repeatability per load cycle, to premature tool wear, and manufacturing high quality parts that meet your standards, on time and within budget.

We have an extensive background in gear arbor fixturing, collet design and build, and chuck repair and build. We have designed and built several dozen hobb and shave arbors with replaceable components while still maintaining .0002″ run out.

This industry continues to evolve at a rapid pace. We believe there is no replacement for service and quality. We offer the highest level of service and the most exceptional quality, while delivering savings that keep you competitive in a global market.

PARTS MANUFACTURING SOLUTIONS

WHY CHOOSE DSU DESIGN SERVICES

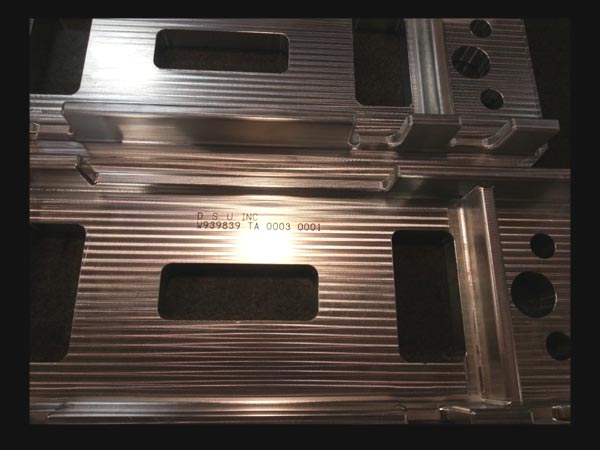

“Design” is in our name, but we are 95% manufacturing and approximately 5% design. While we have an active seat of Solidworks, AutoCAD 2012 and Mastercam X5, our prominent proficiency is intricate-difficult items that other suppliers struggle with.

We have a complete line of hobb, shave and grinding arbors for Transmission pinion gears. We know your existing gear arbors do not have complete working blueprints so we reverse engineer them so you can order any of the components that wear out. Or we take the existing gear arbor, and design a better one to fit within your EXACT machine offsets and clearances. Basically you just load our new gear arbor (in place of your old gear arbor) and cycle the machine as usual. NO OFFSET CHANGES OR PROGRAM CHANGES OF ANY KIND.

We’ve done this in several instances and have lab layout reports that document our unparalleled gear quality. We design and build gear arbors that produce less gear tooth variation and less flank run out than your current gear arbor, GUARANTEED or your money back. We also make Nagel hone fixtures and/or components for them that meet all Nagel repeatability and quality standards.

One great feature we offer is that all of our components in a particular gear arbor are interchangeable across the entire lot of arbors with alike part numbers. We hold all components to stringent tolerances and consider all “stack-up” tolerance variation when making them. Not only do you save money on each assembly, you reduce costs by being able to swap components or buy just the “wear item” from us. The money you save buying from us is already substantial but no comparison to the down time you eliminate through interchangeability.